A work in progress

Following completion of my Bagger 288 model and Marion6360 Stripping Shovel in replica Meccano in 2016 I decided to build the Bucyrus Erie 4250-W Walking Dragline, also

knicknamed Big Muskie on account of the fact that it worked in the Muskingum

coal mine in Ohio, in a similar scale of 18 to 1.This is a scale I like to work

in as it allows modelling of many small details like hand rails and driver’s

cab furniture. One of the reasons I chose to build the 4250-W was that it was

the largest dragline ever built and I would be completing an unholy trinity of

the three largest fully mobile land based machines that ever were. ( My

threesome is completed by the Krupp built Bucket Wheel Excavator with machine

number 288 working for Rheinbraun coal in Germany.) The 288 model weighs in

at 1335kg, the Marion

at about 1250 kg while the B E 4250-W has a weight projected to come out at

1200kg. The ratios between these masses are about the same as those between prototype

masses. Incidentally this makes these models the largest such models in the

world by mass. To my mind mass seems to be the most sensible criterion for

making such a judgement. Using length, height or breadth leads inevitably to an

inconsistent criterion. Number of parts is a bit more reliable but not as

positive definitive as mass.

There were, however, other reasons for choosing Big Muskie .These were

bound up with the fact that many of the operating systems of a dragline were

very different from those of the

previous two diggers ( and digging has always been a part of my life even

though it has been hand digging out more cubic metres of earth and rock in

building the property I live on than I’ve had cooked breakfasts!) The method of

propulsion is completely different, in that the whole machine is lifted up on

two walking supports, each of which consists of two “shoes” hinged together to

allow a small amount of adjustment to allow for uneven ground. In the 4250-W’s

case the lifting was done using four immense hydraulic rams. When not about to

walk the machine sat on a 105 foot diameter “tub” which just rested on the

ground, but when about to walk the tub would be lifted bodily off the ground. The

next step was to slide the machine backwards on the four shoes, using another

four hydraulic rams which worked in an horizontal direction. The machine always

moved backwards due to the fact that it always sat at the top of a cliff face

it was clawing away at and had to be prevented from falling int the hole it was

digging. Stripping shovels on the other hand sit at the bottom of a cliff face

they are digging and so always move forward into the workface. This new mode of

locomotion presented an exciting challenge in effecting its engineering with

Meccano-like components. Big Muskie’s hydraulic propulsion system was different from most other machine systems ,which used the Martinsen

Mechanism. This used What amounted to an enormous eccentric throw on either

side of the machine to move the feet.

The digging action is also completely different. In the stripping shovel

digging was achieved by a combination of “crowding” a bucket forward into the

work face on the end of a long “dipper” handle and hoist action. With

draglines, digging is done by dragging the bucket along the workface towards

the machine and then hoisting. This obviously needs two kinds of winding drums

but crowd action is absent.

The swing action of the dragline is similar except that the whole

machine weight minus tub weight swings on the tub instead of machine weight

minus lower works weight swinging on the lower works. The consequence of this

for me is that total swinging mass will now be close to 1100kg, far more than

the Marion’s

swinging mass of about 700kg.

Bucyrus Erie 4250-W was a giant of a machine, with main boom length 310

feet, height of 220 feet, width of 140 feet and machinery hall height of 65

feet. Mass was some 12500 metric tons, making it the third most massive machine

to walk the planet. The bucket capacity was 220 cubic yards which was larger

than Marion’s

at 180 cubic yards. A photo of the 4250-W at work is shown in Figure 1.

|

| Figure 1.Bucyrus Erie 4250-W at work |

Work on my model started early in 2018 and by the end of the year the

main boom was complete. Figure 2 shows this unit stored in a tight space next

to Marion 6360.

The top end of the main boom is shown in figure 3. This reveals some quite

tricky parabolic shaped plating which I effected using some scrap sheet metal

from an old electric stove and other sources, I felt that a much neater looking

job would result than if I had tried to manipulate standard parts to replicate

the look of the prototype. Also visible in this figure are two rectangular

openings in which will run four 10inch 10 spoke pulleys supporting the four

hoist cables. These pulleys are shown in figure 4. They were laser cut for me

by Steelcut Services of Port Elizabeth from 12mm aluminium sheet. Once again I

must thank Sally Pillay and her team at Steelcut for laser cutting all the

steel and aluminium blanks for parts. The grooves of the pulleys were cut by

myself on a lathe. At this stage I must also thank Roxy Swanepoel at Mr. Screw

of Port Elizabeth for her knowledge and efficiency in supplying some 200 000

fixers.

|

| Figure 1. 18 foot main boom stored next to Marion 6360 |

|

| Figure 3. Top end of

main boom showing some purpose cut plates. |

|

| Figure 4. Four ten

spoke ten inch diameter aluminium hoist pulleys. |

Examining figures 2 and 3 shows that much of the construction was done

using tubular material. It is aluminium tubing of various diameters but a

common wall thickness of 2 mm. The longitudinal members were made from 38 mm

tube. This was all cut into 2.5 inch lengths which had to be accurately sized

in my lathe. These short lengths were then bolted together with a continuous

girder and a continuous strip inside. The reason for this was that a whole

system of joiner cleats had to be bolted on for the lateral and diagonal

bracers to attach and I had to get fingers inside to place nuts. This in itself

was quite tedious but made possible using a fair amount of Prestik ™ to hold

nuts on fingers! The transverse members are 16 mm tube and the diagonal bracers

are 19 mm tube, each section being flattened at each end and bolted with enough

bolts to create a strong join. This is not as neat as the prototype’s welds but

it still looks reasonable. Another criticism is that these sizes of tube are a

bit too large in comparison with a true scale model but then smaller sections

would not have been robust enough. Anyway this sort of thing happens in

Meccano.

|

| Figure 5. Bridge like bracing structure two thirds way up main boom. |

|

| Figure 6. Twelve four inch diameter and six five inch diameter aluminium

pulleys. |

Figure 5 shows a detail of a bridge type structure between the two main

side by side units of the main boom. This serves to give added torsional

rigidity to the join between the two side by side units. The unit will also

serve as a support for four 4 inch guide pulleys to keep the hoist cables from

sagging too much and to also act as a damper on oscillations set up in these

due to resonance. The hoist cables are 5.5 inches in diameter so it would not

do to have them vibrating like giant guitar strings! That would do damage to

the boom. Figure 6 shows a dozen of these 4 inch aluminium pulleys. In total

the model will employ 24 of these to do various

things. At the moment 12 are being temporally utilised elsewhere as I

will show. Also visible in figure 6 are six five inch pulleys with other uses.

|

| Figure 7. One of the minor booms (nine foot) |

At this stage one of the two minor booms which are used to get the

angles right for cables supporting the boom system not to become overstessed

has also been built. It can be seen in figure 7. The mode of construction is

similar to the main boom but now the longitudinal members are 32 mm diameter.

At this stage I will explain one of the most compelling reasons for choosing

the tubular construction mode. Firstly the booms on the prototype are tubular.

In fact if one studies pictures of other draglines it will be seen that this is

virtually universal. Moreover the entire boom system of the prototype was

divided into airtight sections and each was pressurised to seven atmospheres

with nitrogen. These pressures were then continuously monitored and if a drop

in any one was noted the machine was stopped for repair because this meant that

a crack had occurred in a weld. A Meccano girder type boom would not highlight

this feature. Because it was a radical departure from any other technique I had

used I decided to build the booms first.

|

| Figure 8. Motor/gearbox driver unit for vertical lifting |

|

| Figure 9. Slide unit and brass M20 receiving end for M20 rod. |

As mentioned earlier the draglines had a method of locomotion which was

different from other classes of shovel and for me it represented some novel

challenges. So this is what I tackled next. The first thing was to build a

pseudohydraulic lifter capable of lifting over 300 kg .This was done using two

window motors ( which I will call 12V motors from now on) driving an M20

threaded rod through two two stage reduction gearboxes. One of these is shown

in figure 8. The threaded rod in turn drives down into a brass fitting machined

from 50 mm stock with an M20 central thread. At the bottom end a 20 mm hole has

been milled sideways and a 20 mm rod passes through this hole into a strong

slidepiece which can slide horizontally on a pair of 20 mm stainless steel rods

journalled into the top of a walking

foot. One of these is shown in figure 9 in a knocked down view. There are four

of these units, each being driven by a motor /gearbox as detailed above. So

eight 12V motors will lift the 1200 kg machine up onto what are essentially

short stilts. Then to do the horizontal slide (of about 9 inches) a set of four

more pseudohydraulic rams, this time based on M12 treaded rods and employing a

single 12V motor each will do the pushing. In figure 10 all four walking feet

are shown, spaced about as far apart as they will be when mounted.

|

| Figure 10. Walking feet, correct distance apart (overall width 8ft 3 inches) |

In parallel with all this construction has been much part manufacture. Over

9000 plates have been made, the most common one being the 5 by 11 hole , the

total of these being 7000, in gauges 0.6 mm(3000), 1.0 mm gauge (3500) and 2.0

gauge (500).

|

| Figure 11. 61 inch diameter torroidal mainframe suspended from wheeled wooden gantry crane. |

In figure 11 is shown the very strong 22 hole deep toroidal frame of the

machinery hall. It is 61 inches in diameter and so this is the diameter of the swing

roller rail. As with the previous two excavators I will use one piece 3 mm

gauge flat steel strips for these so as to get a smooth strong rail. The

Toroidal frame was created by bolting 64 eleven by seven hole plates together

offset one hole to give the circle with correct radius and then using these to

position 64 bulkheads plated with 1.0 mm 11 by 5 hole plates. 32 of these

bulkheads go in to a 21 inch diameter ring and32 go in to a 41 inch diameter

ring . A final set of 11 small bulkheads go right in to a 10 inch ring so that

a very strong central hub can be created, the need for which is to support the

tub when the machine goes up on its walking feet. All of these smaller circles

are plated as is the outer surface, the latter with a double layer of 0.6 mm

plates lap joined horizontally and butt joined with flat girder joiner coupons

vertically. As can be seen in figure 11 the spaces between bulkheads have a

lattice of girder bracing. The frame is upside down in the picture so no one

will be walking on this circular surface but the reverse surface will serve as

part of the machinery hall floor and hence is fully plated with a pattern of

plates arranged in concentric rings so that no operating staff will fall down

to the tub, which is a long way down. Structurally the frame consists of a

large number of juxtaposed closed boxes and so is immensely strong. Assembling it

was quite a logistic challenge due to the close spacings of bulkheads.

Consequently some special techniques of assembly had to be worked out.

(Needless to say a lot of Prestik™ was involved, )

It will also be seen in figure 11 that the frame is suspended from a

wooden wheeled gantry crane which was specially built for the purpose. This was

necessary as the frame weighs about 150 kg and is an awkward shape for several

people to get hold of. Flipping it over by hand is frightening to contemplate!

There are two geared winches at the top of the crane, each driven by two 12V

motors.

There are also some pulley blocks seen on either side. This is where the

remainder of the four inch aluminium pulleys mentioned earlier are being

temporarily put to use.

|

| Figure 12. 71 inch diameter tub. |

In figure12 the matching toroidal

frame called the tub is shown. This has

a similar structure to the mainframe tub but is only one eleven hole plate

deep. A 61 inch diameter ring of plate onto which a similar 3 mm gauge one

piece roller rail will be fixed is visible. The inner ring structure is similar

but now an extra 5 inch wide ring of

bulkheads has been added on the outside. This increases the tub diameter

to 71 inches, making for greater stability and also will serve as space to

affix another 3 mm strip into which 240

eight mm holes will be fixed with about 20 mm of thread facing outward.

This will serve as a 240 tooth ring gear onto which the final drive

pinions of the swing motor/gearboxes will mesh.

Examination of figure 12 shows another feature of the prototype I am

trying to reflect. This is the two colour paint scheme. Accordingly I have

painted some of the plates green so as to match the green boom system. In fact

looking back at the picture of the walking feet shows the same idea on the

visible plates there. There are also some plates which have been painted green

on one side and red on the other for when one colour needs to show outwards and

the other on the inside. The tub was assembled on a special flat table

temporarily put together to ensure that the structure came out as flat as

possible. Once again the crane was useful for lifting the tub off this table

and in fact turning it sideways so that a strong central hub could be

assembled. This hub will anchor the lower end of the rod which bears the full

weight of the tub and also the brass wheels of the roller race.

Finally the tub was lowered onto a 3 inch high wooden platform made of

multiple box units. The reason for this is bound up in the logistics of fitting

the walking feet. Because the model is so massive I cannot lift it up or turn

it sideways to allow each walking foot to be driven on by the screw thread, I

will have to do this without any boxes under the feet at first and then when

feet are tucked up where they should be for digging finally put boxes in place for

them to come down onto. Fortunately this garage has a very high ceiling so I

don’t have a headroom problem at all.

|

| Figure 13. Shock absorber mechanisms shown rotated through 90 degrees |

At this stage one further mechanism has been completed. This concerns

the two mechanisms shown in figure 13 which will be affixed to the front of the

machinery hall. Each involves four 10 inch ten spoke pulleys. These are

journalled in pairs, one pair in the large fixed unit and the other in the

pendant shaped unit which can swing on the latter unit. The drag cables wind

around these so that when the bucket strikes rock that is too large to drag out

the pendant will swing forwards thus preventing too large a shock going back

and damaging the drag drums. The pendants are weighted so that this does not

happen for virtually no reason. In the case of my model the weight is 4 kg each

unit and it consists of about 1.4 litres of ferrocement which I mix up from cement powder, water and

the fine steel swarf that I have collected over the years from drilling about 2

million 4.2 mm holes. The main machine ballast

will be about eighty sturdy plastic 740 gm mayonnaise bottles filled

with this ferrocement.

The total weight will need to be about 165 kg. (If you are having

difficulty seeing how the described action occurs in the units shown in figure

13 remember that they will be rotated through 90 degrees on the model.)

18th February 2020.

The last two months have been taken up by parts manufacture and the

completion of the main operating machinery. Figure 14 shows representations of

five different types of turned aluminium wheels. There are 108 flanged wheels with 8mm axle bosses. These

are for the main swing roller race (92) and the main support wheels of a five

foot wide servicing gantry crane which runs the length of the machinery hall

and actually comes out an extra foot on an extension rail at the rear. There are

twelve smaller flanged wheels with 4mm axle bosses for the gantry crane cross

traveller. There are 80 bush wheels with 8mm axle bosses, 40mm diameter. These

are for the system of motor/generators (48) and backings to various guide

wheels etc. (32). There are 32 similar bush wheels but with 4mm axle bosses

which will be used for flexible couplings to avoid alignment problems in

various places. Finally there are 12 larger bush wheels, 50mm diameter , to

back the 12 ten inch ten spoke pulleys for the main cable system.

|

| Fig. 14. Representatives of five different aluminium wheels |

|

| Fig. 15. One walking foor with operating slider mechanism |

Figure 15 shows a completed walking foot with the slider unit installed

and its driving motor and pseudohydraulic mechanism now working. The large

brass vertical unit has an M20 thread ready to accept the rotating M20 rod

which is one of four which will lift the whole machine onto its walking feet

when it needs to move. All four of these walking feet have now been fitted out

in the same way.

The four matching drive units for the M20 pseudohydraulic actuators are shown in figure

16. Each is powered by two 12V motors driving through two stage reduction

gearing as mentioned before.

|

| Fig. 16. All four lifting motor/gearbox units (two with M20 brass receiving ends). |

Next the eight swing motor/gearboxes have been built and are shown in

figure 17. I did not have the large 13 tooth final drive pinions for these when

this picture was taken. However I have just taken delivery of these cut from

12mm aluminium stock by Steelcut Services, as shown in figure 18. In figure 18a I have posed two of the pinions on a short piece of 40 by 3 mm strap with M8 bolts acting as the teeth of the main contrate wheel. For the last

two models I cut these by hand using a one hand angle grinder fixed to a table

rather like a butcher uses a band saw. This was very awkward and messy and

lacked the precision of the high resolution laser cutter. My thanks to Sally

Pillay and her team again for a beautiful set of pinions!

|

| Fig. 17. All eight swing motor/gearbox units. |

These final drive pinions will

mesh with a 250 tooth ring gear created

by setting this number of M8 bolts in a 3mm steel strap installed on the tub

with outward protrusions to act as a large contrate wheel. The previous two

models had four swing mechanisms each but now the moment of inertia is larger

due to the larger mass being swung (1100 kg) and the total length of the BE

4250-W at 26 feet. The dimensions of MI are mass times length squared.

|

| Fig. 18. All eight aluminium laser-cut final drive swing pinions. |

|

| Fig. 18a. Two final drive aluminium pinions posed on a short section of ring gear. |

The last of the main actuators are shown in figure 19. These are the

four double sided winding drums, each driven by two 12V motors driving directly

onto 8 inch gears bolted directly to the drum. The latter are fabricated from

two 6 inch face plates at the outsides with a 7 ½ inch face plate at the

centre.(You might notice that the centre units are actually 8 inch light gauge

gears . This was the only error made by Steelcut in 10 years! I didn’t have the

heart to cut them down to 7 ½ inch face plates as they actually mesh with the

12V motor output gears being only one tooth different from the heavy gauge 8

inch gears.). Holding all together are eight M8 rods and nuts. The threads on

the rods have been covered with fish tank plastic tubing to prevent the nylon

covering of the hoist and drag cables being damaged by said thread. A hairdryer

was handy to push the plastic tube onto the rods.

|

| Fig. 19. Four double-sides winding drums for hoist and drag. |

21st March 2020

I have now mounted the swing roller

race rails above and below, 40 by 3mm steel strap on the tub and 50 by 3mm on

the mainframe. The wider strap on the latter accommodates four 12mm holes

through which the four drag cables will feed from the drag drums to the front

of the machine and the shock absorbers. In figure 20 the upper rail can be seen

as well as two of the 12mm holes.

|

| Fig. 20. Mainframe with swing roller rail in place and two 12mm holes visible |

In figure 21 the tub toroidal frame

can be seen with its roller rail installed and the 94 wheel roller race in place

thereupon. The roller race consists of another 40 by 3mm steel strap with 94

eight mm holes drilled at a spacing of 50mm between centres. Each wheel runs on

an M8 bolt which is fixed with a locknut into the strap. The 40 by 3mm strap

which will act as a giant contrate wheel has also been prepared with 267 eight

mm holes drilled at 20mm spacing. There will be 267 M8 cap screws fixed into

these holes with 30mm of thread pointing outwards to act as the teeth of the

contrate wheel. This will be fixed to the tub outside the roller rail. This is

contrary to the prototype which had a planar ring gear inside the roller rail.

The reason for the change is that I want the swing gearboxes to be accessible

without having to dismantle the whole model in case any of them needed

servicing. (I do not have any 4 inch high servicemen who can get inside the

model!)

|

| Fig. 21. Tub with 94 wheel roller race sitting on roller rail |

Figure 22 shows one of the swing

motor/gearbox units with the 13 tooth aluminium final drive gear installed.

While testing these units I was mindful of the fact that if a finger should get

into the rotating gear it would probably be sheared of at the joint since the

torque transmitted here is huge.

|

| Fig. 22: One of eight swing motor/stroke gearbox units with aluminium final drive pinion |

|

| Fig. 23: Four double winding drums mounted on top side of mainframe |

The two double winding drums for

hoist and the two for drag have now also been installed on the upper surface of

the mainframe which is part of the hall floorpan. These can be seen in figure

23. These units were installed with the mainframe held sideways in the wooden

gantry crane. The reason I have installed them at this stage is that that they

are a long way in from the edge and one’s arms are not long enough to do the

job after the mainframe has been placed on the tub. The attachment was a tricky

job as the units are rectangular while the floorpan is radial. A series of

girder lugs was built into the floorpan and these were used in an opportunistic

way, with several flat girders bent with a bend transverse to the said flat

girder to connect the disparate types of structure. Also seen in figure 23 is a

14 inch face plate in 2mm gauge which has been fixed to the centre of the

circular floor. This is bolted to a very strong central hub which was assembled

in the central space in the frame. This will bear the weight of the tub when

the machine is ready to walk, through the M12 rod which supports the tub. This

14 inch face plate is actually the dropout from getting a plate with a 14 inch

hole cut in it for the minor roller race track of my Krupp 288 model. I thought

it would come in handy one day!

Finally during the last month or so

I have built the bucket, using pictures I have to get the details as correct as

possible. There seem to be some differences in detail of various buckets used

on the machine. I know that there were three buckets which were used in

rotation as repairs to any one had to be made every seven months or so due to

the highly stressful job it was doing causing inevitable damage. Qualified

welders were a permanent part of the machine team.

There is a lot of detail in the

bucket so I have included several pictures, namely figures 24, 25, 26, 27 and

28. Figure 24 is a side view while 25 is a view from the front and shows the

six large digging chisels. Figure 26 is an oblique view while 27 is a close up of the way the main hoist chains

are attached using an M8 bolt through two plate thicknesses one inch apart so

that bolts do not get twisted upward by the weight of the unit. Figure 28 is a

view of the rear and shows some heavy strapping effected using three

thicknesses of flat girder to mimic the prototype. These straps go underneath

the unit as well. These all go to make the bucket very strong. I think it could

be filled with a scale load of 35kg. The colouring of the bucket needs some

explanation .While these buckets are working the inside, bottom and some lower

and frontal surfaces become polished to a newly sanded look by the material

being handled. Accordingly I have coloured these areas silver (actually cold

galvanising). The remaining surfaces are a matt black. It will also be seen

that the four main chains have been attached. Many years ago I planned to build

a swing for my children but then changed jobs and found myself in a new town

building a home for my family. Swing never got built and I’m still working on

the home 40 years later! The chain I bought back then proved to be exactly the

size I needed here.

|

| Fig. 24: Side view of bucket |

|

| Fig. 25: Front view of bucket showing drag chains |

|

| Fig. 26: Oblique view of bucket |

|

| Fig. 27: Attachment of hoist cables |

|

| Fig. 28: Rear view showing reinforcing straps |

Figure 29 shows a more detailed shot

of the very strong central hub which has been assembled and which supports the

14 inch diameter plate which has in turn been reinforced with a 5 by 15 hole

2mm gauge plate bent down the middle to form a girder.

|

| Fig. 29: Strong central hub with 14 inch face plate |

Some more work has been done on the winding

drums in figure30. This shows protective cowlings mounted over the 8 inch drive

gears. Also over four of them observation platforms have been installed to

allow engineers a vantage point from which to observe the revolving drums to

check for any possible malfunction. Short sections of ladder will connect these

to a network of staff gangways to be installed. Also seen in these pictures are

sixteen “cosmetic” representations of the sixteen 1000 horsepower motors which drove the winding drums on the

prototype.

|

| Fig. 30: Some cosmetic work on winding drums and correct length cables installed |

At this stage all eight individual drums have

had sufficient cable installed to enable the machine to send a bucket down 10

feet, which is the scaled equivalent of the 185 foot depth of dig on the

prototype. This is 13 metres on the drag drums and 18 metres on hoist drums.

Braided steel cable of diameter 2mm with nylon covering has been used. I am

confident that the drums and cables are sufficiently strong to drag and hoist a

scaled load of about 35 kg but of course I will not be doing that as my

gearboxes are all open and would not be able to handle grit getting into them.

Finally I have wheeled the mainframe

over to the tub and lowered it so that it now rides on the 94 wheel roller

race. The M12 rod has also been manoeuvred into position and the nuts keeping

the two units together when the tub is lifted off the ground have been fitted. This

work is shown in figure 31.

|

| Fig. 31: Upper toroidal frame sitting on tub with roller ring between |

The future order of building will be:

- Install

the eight swing Units together with the 267 tooth swing contrate gear.

- Build

the toroidal mainframe out to a rectangular floorpan, 6 inches in the

front and sides and 30 inches at the rear.

- Mount

the four lifting units to the outside of the floorpan structure.

- Mount

the walking feet.

- build

the machinery hall out another 6 inches on either side.

- Mount

the frontal shock absorber units.

- Build

the gantry.

- Install

entire boom system (already built) and hoist into final position being

careful to have about 250 kg ballast in place at machine rear. To do the

hoist I will remove the two winches from the wooden crane and install

these temporarily on the machine gantry.

- Install

system of motor generators on rear of hall floor.

- Build

cabin enclosure, slowly reducing ballast to 160 kg.

The 267 tooth contrate wheel has now been

assembled. The teeth are M8 countersunk CAP screws with 30 mm thread protruding

out from a one piece strap of steel, 40mm by 3mm.The eight swing motor/gearbox

units have also been installed and wired up. Figure 32 shows these

developments. Figure 33 shows the top of the toroidal frame loaded with some

boxes containing 300 kg new plates to

provide some additional weight for testing the swing units.

|

| Fig. 32. The swing motor/gearboxes on one side. Also the contrate wheel in place. |

|

| Fig. 33. Boxes containing an extra 300kg of parts to test swing. |

The next step is to develop the 61 inch

circular frame out to a six foot square

frame . The connection between frames will be 64 bulkheads bolted to the outer

girders on the toroidal frame coinciding with the 64 inner bulkheads of said

frame. These vary in width from 5 inches to 20 inches and are all fully plated

with 1mm gauge 11 by 5 hole plates using a high bolt density as they need to be

very strong. The four lifter units will be attached to the outsides of the

square frame and hence very large force and very large moment will be exerted.

The bulkheads are all 22 holes deep except for those which are 11 holes deep,

necessary to make room for the swing units. Some very strong lower chords will

need to be installed in order to even out the distribution of stress.

|

| Fig. 34. 64 bulkheads joining toroidal frame to outer square frame. |

|

| Fig. 35. View down one side of square being created. |

Figure 34 shows the 64 bulkheads from above

while figure 35 shows the straight edge formed by bulkheads on one side. At

this stage the four outer edges of the frame have also been assembled and one

is shown in figure 36. The sides are 72 ½ inches while the front and back are

73 ½ inches. The extra inch was added to give clearance for the swing drives.

|

| Fig. 36. One of the four sides fully assembled |

The next task is to attach the four sides of

the square. This will need some fettling and adjustment. I have some 110 degree

and some 135 degree obtuse girders to start with. These angles can be adjusted

in a vice to suit. Some extra slippage will also be necessary.

So far so good in figure 37 which shows the

sides in place, bolted at the corners and the midpoints for now.

|

| Fig. 37. All four sides mounted and reading for joining to bulkheads. |

July 1st 2020

The view shown in figure 38 looks very similar

to that shown in figure 37, except for an increase in the number of bolt heads

visible. This is because figure 38 shows the machinery hall frame with all 64

of the connecting bulkheads between the toroidal frame and the square frame now

fully bolted up to create a very strong structure .From figure 37 to figure 38

there are an additional 2000 bolts and much obtuse girder and flat girder

material. Since virtually every bulkhead connects at a different angle and a

different distance this job required much fettling by way of obtuse angles

adjusted slightly in a vice, many 4.2mm holes reamed out to 6mm for extra

slippage, some flat girders with an extra 1/16 inch between the hole lines and

some strips for fine adjustment. |

Fig. 38: All 64 bulkheads between toroidal frame and square frame connected

|

With the floor mainframe completed I could

start attaching fittings which go onto the structure. Figure 39 shows the

pseudohydraulic lifter motor/gearboxes fitted to the right side of the machine.

Figures 40 and 41 are close ups of each of these. The attachment has to be

immensely strong since each unit experiences an upthrust of nearly 300 kg when

the machine goes into walking mode. Accordingly, the lower chord of the

mainframe has been reinforced with 2mm gauge plates so as to spread the load

out to as large an area as possible and not let it impinge on the toroidal

frame as a point load. Visible in figure 40 are two specially bent 2mm plates

which will connect each lifter to the lower frame chord.

Also visible in the above figures are very

strong 7 inch high posts which will be connected to an anchor point on the

outer floor, which itself will be plated in 1mm plate for a very strong floor.

This will reduce the effect of the moment of force exerted by the lifter unit

on the side of the square frame.

A similar plate structure has been built onto

the lower side of the mainframe to help distribute the force exerted there by

the lifter mechanism.

|

Fig. 39: Lifter motor/gearbox units on right side of machine

|

|

Fig. 40: Right rear lifter

|

|

Fig. 41: Right front lifter

|

At the front face of the square frame the two

shock absorber units for the drag cables have been fitted. These are shown in

figures 42 and 43. The eight ten inch ten spoke wheels have been posed in place

too.

|

Fig. 42: Drag cable shock absorber

|

|

Fig. 43: Another view

|

Figure 44 shows some work on the right front

face to install the supports for the boom system (green plate.) The heavy gauge

plates in red are actually inside the hall and are supports for the right front

strut of the gantry. These have 10mm

holes for an M10 bolt. The boom system will be supported by m12 bolts.

|

Fig. 44: Support for boom system and for front right gantry member

|

Figure 45 shows a view from the rear. There are

nine vertical girders bolted onto this face to receive the nine bulkheads which

extend over two feet to create a large box at the rear of which will be placed

about 165kg of counterbalance ballast in the form of 80 bottles of ferrocement

as explained earlier.

|

Fig, 45: Rear view where large box will be installed, with ballast at the rear.

|

Finally, by way of an advance experiment, I

have built the roof truss and a floor truss for the mezzanine floor which

supports the air filtration plant for cooling air. These are shown in figure

46.

|

Fig, 46: Roof truss and combination roof and floor truss for air filtration units in mezzanine floor

|

August 22nd 2020

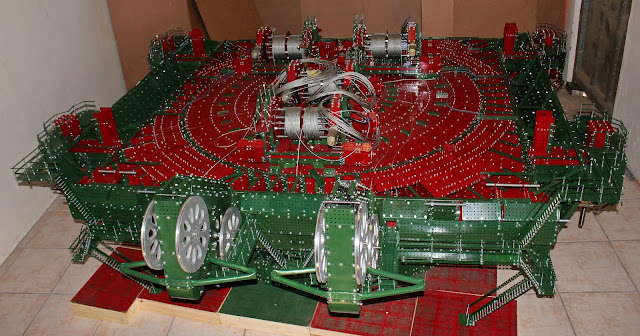

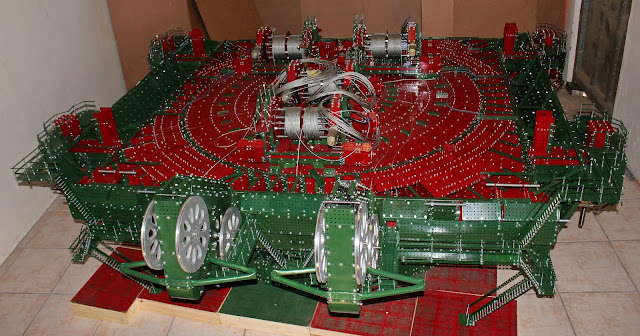

At last the model is showing some completed

outer surfaces and features. The lower front end is now complete with its

stairs and walkways for staff to get onto the machine and to observe the eight

large pulleys of the shock absorber units checking for any malfunction. Note

that all this work is in green in accordance with my version of a two colour

scheme. These can be seen in figures 47, 48 and 49.

|

Fig. 47: View of front end showing access stairs and walkways

|

Figure 47 focuses on the left side of the

machine showing the path from the ground up to a walkway which runs along the

entire machine front and then on up to an observation platform around the top

of the front left lifting unit.

|

Fig. 48: Close-up of strong supports for boom system and front end of gantry

|

Figure 48 is a similar shot but taken from

further back and shows also the M12 bolt support for the left side of the main

boom, the M12 bolt support for the left minor boom and in red (because it is

actually the machinery hall) the M10 bolt support for the left front gantry

stanchion.

|

Fig. 49: Shock absorber units

|

Figure 49 focuses on the shock absorber units.

The fittings made of aluminium tube bent to shape are motion limiters to

prevent the pendants from swinging out too far. On the prototype these do not

feature in early photographs so they were a retrofit. Also obvious from a

comparison of early and later photographs is the retrofit of extra bracing of

the front, which is reflected in my model in the section of strut using 135

degree obtuse girders which goes across the whole width. Engineers must have

found that front was taking a pounding from the drag action.

|

Fig. 50: Overall aerial view

|

Figure 50 is an aerial view of the main body so

far. All four of the lifter units have been fitted and some exterior cowling to

these has been built. Observation platforms are also now showing on these. The

final full width of the hall building is now showing in figure 50. The main supporting

structure is the same width as the square mainframe (all in red) but sideways

extensions to this are seen on either side (in green). These will not go the

whole length of the hall. These form two “lugs”, one on either side. Making

matters more complicated is the fact that the two lugs are not the same height!

I think this might have had something to do with a system of large air ducts

carrying cooling air down from a filtration plant on a second, mezzanine floor.

Also visible in figure 50 is some more floor

plating . This has been done in 1.0mm gauge plate and is very strong. This will

help spread the large force exerted by the lifter unit when the machine gets

ready to walk. Similar plating has been done on the underside of the body for

the same reason. Here the force will be outward.

|

Fig. 51: Left side valence

|

Figure 51 shows an angled valence which forms

the support to the above mentioned lugs. This is relatively lightly built as it

only has to support about 10kg. The main weight of the machinery hall walls and

roof, as well as the air filtration plant (about 200kg) will be supported by 12

strong vertical stanchions rising off the floor. Another 12 lighter stanchions

will support rails for a servicing crane which runs the length of the machine

and actually out the back. Also visible in figure 51 is the M20 spindle of a

lifting unit.

|

| Fig. 52: Close up view of several systems |

|

|

Several different systems are represented in

figure 52. Firstly the 13 tooth drive pinions of two of the eight swing drives

are obvious. Then part of the 267 tooth contrate wheel formed from M8 bolts

protruding outwards from a 3mm thick steel belt is visible. Measures to

withstand the enormous moment exerted by the lifters are represented by several

things in this figure. Straps of 2mm plate connect the bottom of the lifter to

a heavily made lower chord of the mainframe (also employing 2mm plate). At the

centre of this chord is a section of 3mm girder necessary to get past the four

swing units on this side. Finally some of the 94 aluminium flanged wheels of

the roller race ride between upper and lower rings of 3mm rail.

|

Fig. 53: Rear view of side valence

|

Figure 53 shows some coachwork needed to

terminate the angled valence at the rear. The back face of the machine shows in

red because there is still a large box to be built at the rear, extending about

30 inches back and housing 165 kg of counterbalance ballast in the form of 80

bottles filled with ferrocement as explained earlier.

I am grateful to Mrs. Lynette Rudman for her

skilful camera work in figures 47 to 53 inclusive.

October 23rd 2020

Considerable work has been done during the last

few months, some of it cosmetic and some decidedly not so, being heavily built

members of one sort or another. Looking at figure 54, an overall aerial view,

the most evident new work is the main gantry which can be described as two

A-frames side by side with two joining crossbars between the front two members

and then four angled braces between said crossbars. The front struts are each

bolted to the mainframe with M10 bolts and nuts going into angle brackets made

from 2mm material. These struts will be in compression when the main boom is

fitted. The rear struts are bolted into some bent 2mm plates going deep down

into the mainframe at the rear. These will support great tension.

|

Fig. 54: Overall view at present

|

The front struts are box girders formed by

laying 9 by 5 hole 0.6mm lap joined

plates between angle girders in the four corners. Additional strength is

provided by having a flat girder in each corner, butt joined wit lap joined

four hole long flat girder coupons. For additional rigidity lateral bulkheads

are sited every 16 inches along the inside. The two rear struts as well as the

two cross members are similarly constructed but are now only seven holes wide,

using 11 by 7 hole 0.6mm plates.

The front and rear struts are joined with at

the top with more M10 bolts and nuts. Looking at a side view of the gantry in

figure 55 one can see that the gantry is flat topped at this stage. It will

eventually be extended upwards to a point

by means of some 2mm plates. At the apex will be some 4 inch aluminium

V-pulleys which will be part of the boom lifting mechanism. In fact there are

already four such pulleys running in strong journals at the top of the gantry

crossbar, as seen in figure 54. The boom support system consisting of 12 M5

threaded rods will also be anchored to the 2mm plate construction just

described.

|

Fig. 55: Note flat topped gantry

|

Moving to the rear figure 56 shows the tapered

side of the rear box which has now been completed. This will house the

counterbalance ballast. The lower floor of the box is made fro 1.0mm plate, as

are the nine bulkheads extending rearwards. The upper floor, which forms part

of the whole machinery hall floor is made of 0.6mm plates as it does need to be

as strong as the lower floor. Figures 57 and 58 show two views of the motor

generator park which is bolted to this upper floor. There are six high voltage

motors powered by the incoming 13800 volt three phase power driving four

generators each. The latter provide low voltage DC power for all the machine’s

many motors. The torque characteristics of DC motors are better than AC motors

and also 13800 volts is too high for safety. Total maximum power is 62000 horse

power so one can deduce that each HV motor is very powerful. I presume some

power is put through transformers to provide

low voltage AC for lighting, the operator’s kettle for coffee etc.

|

Fig. 56: Tapering box-like extension to the rear

|

The M-G park employs some recycled material in

the form of plate cut from old coffee tins and the round bodies of the HV

motors from the same source. The ersatz rotors of the generators are the tops

of Rustoleum spray paint cans cut and pushed together. The ersatz stators are

stacked washers. To avoid alignment problems, the common shaft to each unit is

journalled in only four points and also employs a flexible drive unit on either

side of the motor. Each of these consists of two aluminium 8 hole bush wheels

and a diaphragm of 3mm insertion rubber. These bush wheels are for the 4mm rod

system while the bush wheels which form the ersatz bearing boxes of the

generators are for the 8mm axle system, so 4mm axles actually don’t touch. Each

unit spins freely and I would have liked to have them turning but I have been

unable to source enough small Meccano motors for this. Also Visible in figures

57 and 58 is a comprehensive system of walkways and guard rails to allow the

electricians to walk safely in M-G park.

|

Fig. 57: Motor, generator park, showing 6 MG units

|

|

Fig. 58: M-G park again. Note walkways with handrails.

|

Figure 59 shows a view from the rear in which

some of the eight holes through which the ballast will be fed are visible. Also

visible is the lower outer corner plating which employs some 0.6mm plate bent

to a tight radius. The 4250-W had these rounded corners in many places.

|

Fig. 59: View from rear showing some holes to place counterbalance ferro-cement.

|

Figure 60 shows another bit of successful

recycling .This is a set of nine cooling fans from old scrapped computers which

were kindly donated to me by Mr. Pieter Burger, our local recycling guy in

town. I intend mounting these around the walls of the machinery hall , imitating

the extractor fans on the prototype.

These are just about the right size and being 12V I will be able to have them

spinning!

|

Fig. 60: Nine cooling/extractor fans from scrapped PCs (compliments of Mr Pieter Burger!)

|

|

Figure 61 shows all 12 of the main vertical

supports to roofs and air filtration plant floor, the latter being situated

above M-G park. These are all channel girders consisting of two girders and a

three hole wide plate each in cross section. The longer six go right up to the

top of the machine to support the roof of the air filtration plant.

|

Fig. 61: All twelve main upright support stanchions for machinery hall

|

Figure 62 shows one roof truss, one mezzanine floor truss and two combination roof/floor trusses. The latter units will support the large air filtration plant in a mezzanine floor to the rear of the maching.

|

Fig. 62: One roof truss, one mezzanine floor truss and two combination roof/floor trusses.

|

Once again I express my thanks to Lynette

Rudman for her skilful photography in figures 54 to59 inclusive.

December 10th

I have now started the large machinery hall

enclosure. There will be about 2500 plates in this structure, mainly 11 by 5

hole in the 0.6mm gauge, with most being drilled around the perimeter only. The

reason for this is that I wanted to avoid an appearance of excessive “

busy-ness” in such large surfaces. In places where I need to put in some bolts

through the middle of a series of plates I have used more standard looking full

face drilled plates in line with the familiar flat plate of Meccano.

|

Fig. 63: Front view showing guide pulleys as well as roof, built back to start of upper floor

|

Fig. 64: Close up of guide pulley support structure

Figure 63 shows a view of the hall front as

well as the roof decking as far back to where the second or mezzanine floor

supporting the air filtration plant will start. At the centre of the upper edge

with the roof is a structure which houses four guide pulleys to get the four

hoist cables safely out the machine hall. Some careful scale drawings were made

to ensure that the cables did not touch the roof trusses or anything else.

Remember that these cables come off winding drums set one behind the other. Figure

64 is a close up of this structure, showing the four 5 inch aluminium V

pulleys. Examination of figure 63 also clearly shows the curved edge between

roof and front wall. This was effected using 11 by 5 hole plates in 0.6mm gauge

with 8 holes reamed to 6mm and curved in the vice. Although there are no

girders in these corners the tight curve on the said plates gives a lot of

rigidity.

|

Fig. 65: Corner showing three curved edges coming together and short piece of rain gutter.

|

Figure 65 shows a corner where three curved

edges come together. Also visible at this corner is a section of rainwater

gutter made by putting two longitudinal bends into a 3 by 11 hole flexible

plate (actually recycled from old coffee tins, a brand which does not come in

corrugated tins!) The downpipes will be 8mm wooden dowels painted red.

The 12 main stanchions which bear the weight of

the roof and also brace the walls are being installed as I move from front to

rear. The rear 6 of these go right up to the roof of the second floor and also

support the floor trusses of this structure. The second floor will house the air

filtration plant. I have not been able to find any details on the latter. There

are a number of walkthrough videos of the interior of the machine but none go

up to the second floor. Also most videos I’ve seen are very shaky and don’t

seem to have any plan to them.. Hence I’ve had to make some guesses at the

layout of the air filtration plant. One thing that mystified me for some time

has been clarified by a very sad picture of the 4250-W taken just before it was

scrapped and a lot of the plating had been removed. I always wondered why the

two side “lugs” on the hall were asymmetric, rising to different heights. In

this picture there is a clear view of a large air duct at the top of the higher

of the two lugs. The purpose was probably to bring cooling air forward to the

front of the machine. In figure 66 I show an S-bend followed by a left turn in

the air duct to be installed. I have painted the air duct silver to imitate the

galvanised sheet metal of the prototype.

|

Fig. 66: S-bend followed by left hand turn in air duct

|

Figure 67 shows this same fabrication installed,

revealing the need for its strange shape .The rear section of the duct will link up to two large impellor

pumps while the side section has two outlets which play over the winding drum

area. On the other side of the filtration plant two similar pumps will cool the

M-G park. Figure 68 shows this same area being plated over, and the rather

peculiar shape of the side of the hall is now revealed.

|

Fig. 67: Air duct installed

|

|

Fig. 68: Same as Fig. 67 now with some body plating

|

Figure 69 is a shot taken into the rear of the

hall. It shows the other side of the air duct as well as the roof trusses of

the main roof. Paired with each main stanchion there can be seen a second

smaller one which holds up a rail for the 5 foot wide service gantry crane.

Part of the installed rail can also be seen. The clearance between the top of

the rail and the bottom of the roof trusses is 5 inches. I have got the design

height of the crane down to 4.5 inches so clearances are tight but workable.

Note also that the clearance with the air duct is similarly tight. Throughout

the model small clearances between large units has been a recurring theme,

making the BE 4250-W the most challenging build of the three mega models.

|

Fig. 69: View into hall, showing air duct, gantry crane rail and main and auxilliary stanchions

|